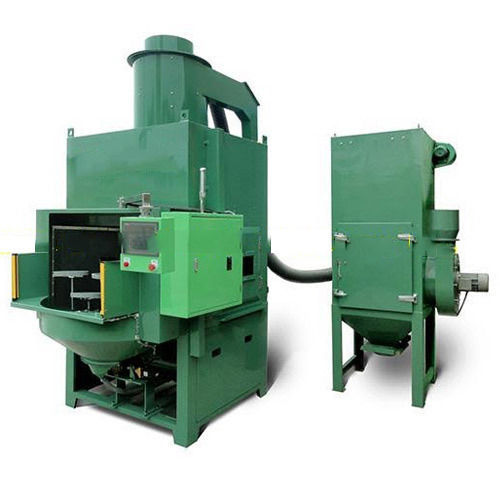

Indexing Table Type Deflashing Machine

Product Details:

X

Product Description

It is a Indexing Table Type Deflashing Machine. It is ideal for medium to large products made from PA (with more than 40% glass fiber, PPS, LCP, PBT or PET. Thermoset products such as bakelite, BMC, SMC are also applicable. It also deals with large zinc-alloy products and other alloy castings.

The deflashing process is simply as below. Firstly, products are fixed on a gripper which locates outside a resolving door. The door turns exactly at 180 degree driven by motor and sends the products to designated position in the blasting room. Products will rotate themselves as driven by rotary motor. Meanwhile, 12 guns throws out nylon shots bumping into products. When deflashing time is up, the door automatically indexes out those finished products and at the same time indexes in products to be deflashed. It is quite an automatic circulation system.Customer can choose computer control or manual control. As for computer control, one press only can start the whole system and achieve continuous deflashing.

The deflashing process is simply as below. Firstly, products are fixed on a gripper which locates outside a resolving door. The door turns exactly at 180 degree driven by motor and sends the products to designated position in the blasting room. Products will rotate themselves as driven by rotary motor. Meanwhile, 12 guns throws out nylon shots bumping into products. When deflashing time is up, the door automatically indexes out those finished products and at the same time indexes in products to be deflashed. It is quite an automatic circulation system.Customer can choose computer control or manual control. As for computer control, one press only can start the whole system and achieve continuous deflashing.

Request

Callback

Callback

Enter Buying Requirement Details