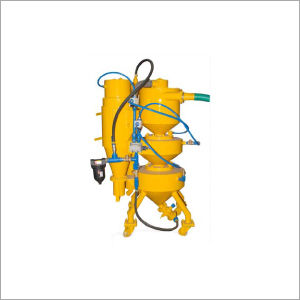

Swing Table Blasting Machine

Product Details:

Swing Table Blasting Machine Price And Quantity

- 100 Kilograms

- 1 INR/Kilograms

Swing Table Blasting Machine Trade Information

- 500 Kilograms Per Day

- 1 Week

Product Description

With an aim to fulfill varied needs of different industrial applications, we are affianced in providing technologically advanced Swing Table Type Blasting Machine. This machine is manufactured using superior grade components and ultra-modern technology in line with defined global market standards. Broadly used for cleaning and removing the sand in fasten time, this machine is highly appreciated for its robust construction, easy operation and hassle free performance. Moreover, this Swing Table Type Blasting Machine is available in various technical specifications as per the diverse needs of our prestigious clients.

Features:

-

Impeccable performance

-

Easy operation

-

No maintenance

-

Longer service life

Previously cleaning with chisel, hammer, wire bushes and screw drivers and other tools for cleaning and removing sand, rust was taking long time, with wheel type shot blasting machine surface finish is achieved in 10 to 15 minutes. Some of the foundries are shot blasting 30 to 40 tones of castings in 12 hours. Shot blasting Improves quality, reduce rejection, saves power and cutting tool cost and adds to the profitability of foundry, forging shops and auto component manufactures. Many small scale units doing job work on this type of machines. Swing Table Type Machines are available with Single Door or Double Door. In this type of machine casting, forging or cylinder heads etc. Must be positioned on table and repositioned to assure complete cleaning of full surface. Component like electric motor body, clutch housing, water pump casing and other components which are fragile, which cannot be tumbled can be successfully shot blasted in swing table machine.

| No. of Doors | Door Table Diameter | Table Load Capacity (kegs.) |

| Single/Double | 900 | 300 |

| Single/Double | 1200 | 800 |

| Single/Double | 1800 | 2300 |

| Single/Double | 2400 | 4500 |

Note: Additional bigger size available on request.