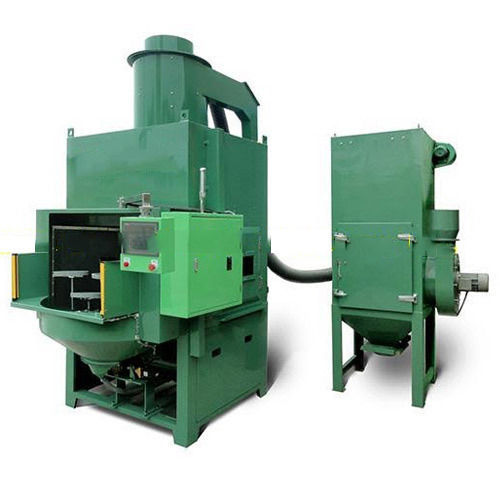

Automatic Tunnel Type Continuous Deflashing Machine

Automatic Tunnel Type Continuous Deflashing Machine Specification

- Power Consumption

- Low

- Phase

- Single/Three Phase

- Automation Grade

- Automatic

- Frequency

- 50-60 Hz

- Power Source

- Electric

- Application

- Deflashing

- Warranty

- 1 Year

- Type

- Continuous

- Condition

- New

- Motor Type

- Induction Motor

- Material

- Mild Steel

- Power

- 5-10 kW

- Voltage

- 220-380 V

- Dimensions

- Customizable

- Input Voltage

- 220-240 V

- Rated Capacity

- High

About Automatic Tunnel Type Continuous Deflashing Machine

It is a Automatic Tunnel Type Continuous Deflashing Machine which is specialized in deburring big thermoset products. It consists of three self-sufficient deflashing cabinets which in total has six turbines which ensures the largest abrasive projection speed and achieve highest efficiency.The transportation of such thermoset products is a straight line as moving on a belt, which ensures the integrity of those products as getting rid of scuffing. The running speed of the belt can be adjusted as products need. Abrasives, blast by impellers rotating at high speed, hit on products all over. It can even deal with tiny holes where hand can hardly reach. Operator can adjust the deflashing rate and the speed of the conveying belt as products need.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS